AIR HANDLING

AIR HANDLING UNIT

HI AIR KOREA(HAK) AIR HANLDING UNIT is designed to withstand and optimally operate in some of the harshest conditions in marine.

All of our unit are built considering size, efficiency, reliability and maintainability. Our AIR HANDLING UNIT is a cost effective unit that can comply with the stringiest requirements of global standards.

HAK AIR HANDLING UNIT is specifically constructed to operate in various applications such as Bulk Carrier, Product Oil Carrier, Crude Oil Tanker, LPG Carrier, LNG Carrier, Container ship, etc. The AIR HANDLING UNIT is required to be built using sturdy and quality materials so as to preserve and prolong the life of the units. The unit is developed in close cooperation with major customers, able to meet the most demanding requirements.

Truly a customizable unit for every application!

-

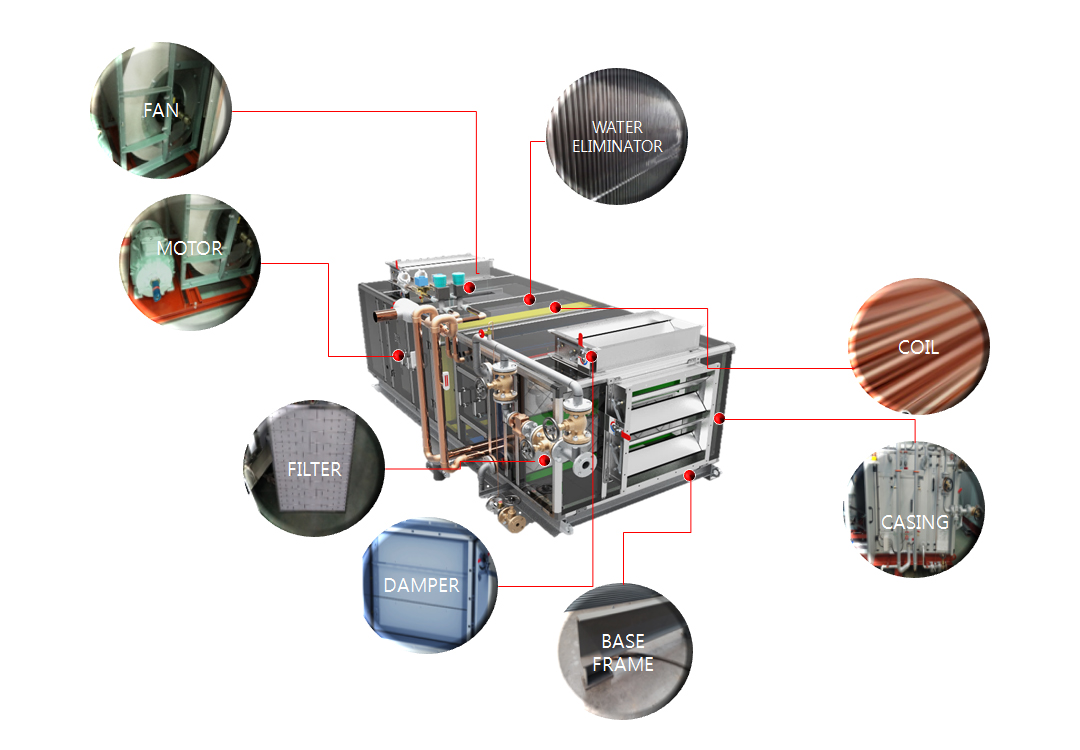

FEATURES

CASING

- 0.6~0.8 mm thick double skinned panels made of galvanized steel internal wall and external wall

- Galvanized steel frame, removable panels and doors

BASE FRAME

- The base frame is made of carbon steel

- Rigid in designed to support all components during shipping, lifting and operation

- Spaces between the frame are also considered for installation of drain piping

DAMPER

- Manual or motorized shut-off dampers can be provided on all AIR HANDLING UNIT inlet and outlet(Aluminum)

FILTER

- 1 stage G4 type filter

COIL

- Coils available are for heating and cooling

- Copper tube with aluminum fins cooling coil

- Cooling medium : HFC refrigerants(R-404A, R-407C, R-134a)

- Heating medium : steam

HUMIDIFIER

- Humidification method : water spray

WATER ELIMINATOR

- Made from aluminum with blades

- 100 % efficiency at velocities ranging from 0.48 to 3.51 m/s

- 55 Pa pressure drop at 2.5 m/s air velocity

FAN

- Centrifugal type with double inlet

- V-belt driven

MOTOR

- Minimum IE 1 efficiency

- Cast iron casing

- IP 55 protection

- Power supply : 380/440/690Vac, 50/60Hz, 3-phase

-

OPTIONS

CASING

- 1.0~1.5 mm thick double skinned panels made of SS316L or SS304 internal wall and external wall

FAN & MOTOR

- Spark proof fans

- Plenum fans

- Explosion proof motors

ADDITIONAL COMPONENTS

- Dampers for supply, return and fresh air connection(SS304 or SS316L)

- Air filter(F5~F9)

- Heating medium : hot water, thermal oil, electric

- Humidification system : Evaporated type, electrode type

- SS304 or SS316L Water trap

- Other refrigerants are available

-

CAPACITIES

No. AHU type AHU dimension Air flow rate Static

pressureMotor

outputCooling

coilHeating

coilFace area W(mm) H(mm) L(mm) (㎥/h) (pa) (kW) (Row) (Row) (m/s) 1 HKA-13/008 1,417 917 3,150 6,700 ~ 9,330 2,000

~ 2,6006.3 ~8.6 8 ~ 14 1 ~ 2 2.0 ~ 3.2 2 HKA-13/011 1,420 1,200 3,460 7,940 ~ 11,050 8.6 ~ 12.7 3 HKA-13/012 1,417 1,317 3,890 10,350 ~ 14,400 12.7 ~ 17.3 4 HKA-15/013 1,660 1,580 3,865 11,920 ~ 16,580 17.3 ~ 21.3 5 HKA-18/012 1,947 1,467 4,055 14,900 ~ 20,730 21.3 ~ 25.3 6 HKA-18/015 1,947 1,617 4,055 18,710 ~ 26,030 25.3 ~ 34.5 7 HKA-18/15L 1,947 1,617 4,515 21,110 ~ 29,370 34.5 ~ 42.6 8 HKA-18/18L 1,880 1,790 5,246 25,000 ~ 34,790 34.5 ~ 42.6 9 HKA-21/21L 2,200 2,200 6,200 35,100 ~ 48,840 42.6 ~ 51.8 - Standard of Humidification system : water spray

- DOCUMENTS