COOLING

CHILLED WATER UNIT FOR MGO

Due to the regulation on Sulphur emission caused by heavy marine fuel oil consumption, IMO MARPOL Annex VI 2008, EU Directive 2005/33/EC, and California Air Resources Board(CARB) are now requiring the shipping industry to use fuel oils with lower percentage of Sulphur.

In response to this, a new type of low Sulphur fuel(Marine Gas Oil) has been developed of which viscosity is very low, so the performance of fuel pump are deteriorated.

HI AIR KOREA(HAK) takes the design challenge to keep the viscosity and lubricity of low Sulphur MGO at safety limits to avoid fuel pump break down.

HAK CHILLED WATER UNIT FOR MGO’s efficient fuel temperature control via PLC system ensures proper level of viscosity even at lower loads. Means of cooling are direct and in-direct cooling type.

HAK CHILLED WATER UNIT FOR MGO system guarantees great service even when switching to low Sulphur fuel!

-

FEATURES

CERTIFICATION GUIDELINE

Regulations Date Area Limit sulphur IMO MARPOL Annex VI 2008 01-Jul-2010 Baltic SECA & North sea 1.0 % 01 Jan-2015 0.1 % EU Directive 2005/33/EC 01-Jan-2010 All EU ports & inland waterways 0.1 % California Air Resources Board

(CARB)01-July-2009 The coast in 24-mile from California MDO : 0.5 % MGO : 1.5 % 01-Jan-2012 0.1 % Marine Distillate Fuels(ISO 8217:2010)

Parameter Unit Limit DMX DMA DMB DMZ Density at 15 ℃ kg/㎥ max. - 890 890 900 Viscosity at 40 ℃ ㎡/s2 min. 1.4 2.0 2.0 3.0 Viscosity at 40 ℃ ㎡/s2 max. 5.5 6.0 11.0 14.0 Flash point ℃ min. 43 60 60 60 Sulfur % max. 1.0 1.5 2.0 1.5 Limit for Viscosity at inlet to Engine

In order to ensure a satisfactory hydrodynamic film between fuel pump plunger and diesel oil at inlet to engine barrel ENGINE require a minimum viscosity of 2~3 cst of diesel oil at inlet to engine

Viscosity at 40 ℃ Temperature to obtain Viscosity of 2 cst to obtain Viscosity of 3 cst DMX 1.4 cst 17.4 ℃ -3.0 ℃ DMA 2.0 cst - 18.0 ℃ SELECTION

- Wide range of cooling capacities from 30 to 200 kW

- Customized design for marine applications

CONSTRUCTION

- High quality integrated components for maximum reliability

- Robust shell-and-tube condenser for fresh water

- Equipped with refrigerant filter and drier system

- Simple and compact design for onboard space limitations

- HFC refrigerant : R-407C

- PLC system

- Hot gas by-pass for low load operation

- In-direct expansion type evaporator

MAINTENANCE

- Easy installation and maintenance

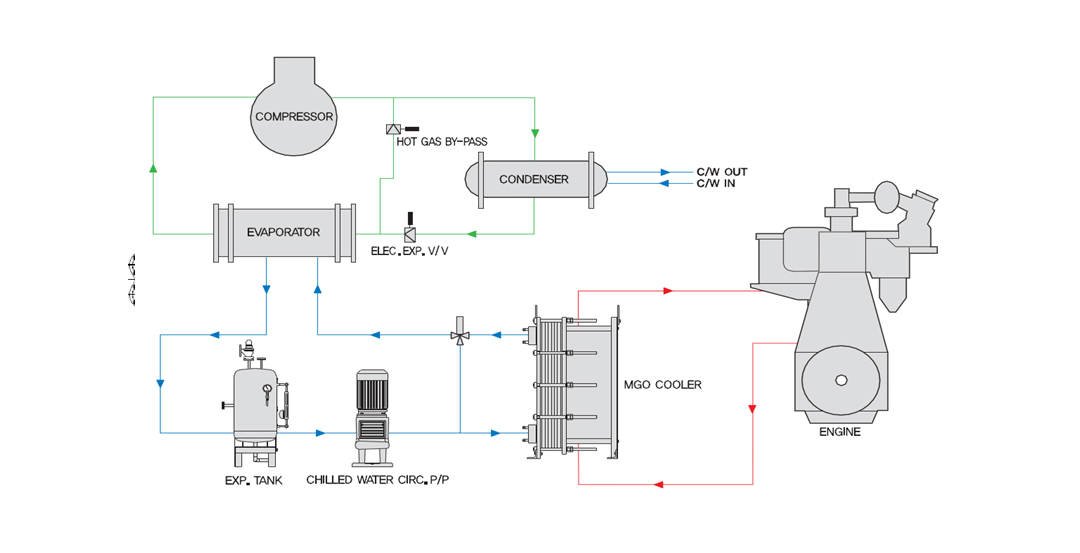

PIPING DIAGRAM

-

OPTIONS

- Robust shell-and-tube condenser for sea water

- Direct cooling system

- Reciprocating type compressor

- Other refrigerants are available

-

CAPACITIES

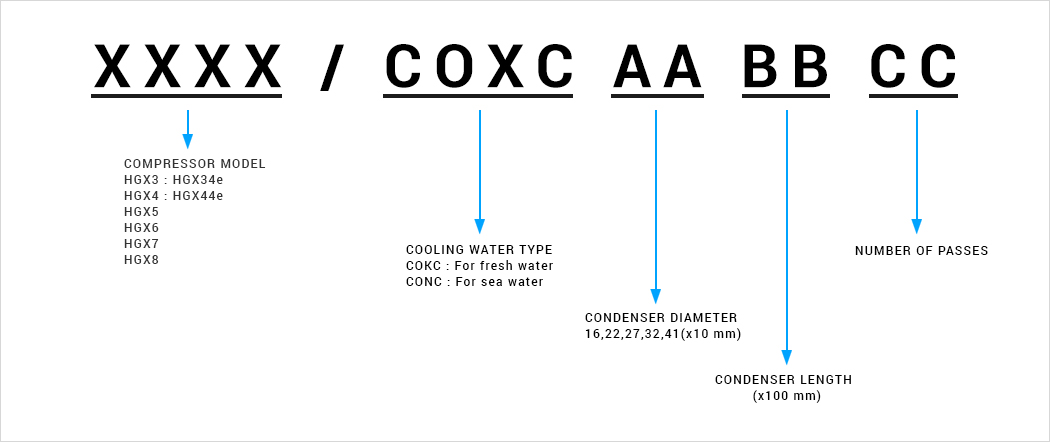

STANDARD TYPE CHILLED WATER UNIT FOR MGO

- REFRIGERANT : R-407C, POWER : 440Vac/3Ph/60Hz, EVAPORATIVE TEMP. : 7.5 ℃

- COOLING WATER : 36 ℃, SUPERHEAT : 10 K

HGX4-465

COKC 161502HGX6-1240

COKC 211902HGX7-1860

COKC 271902HGX8-2470

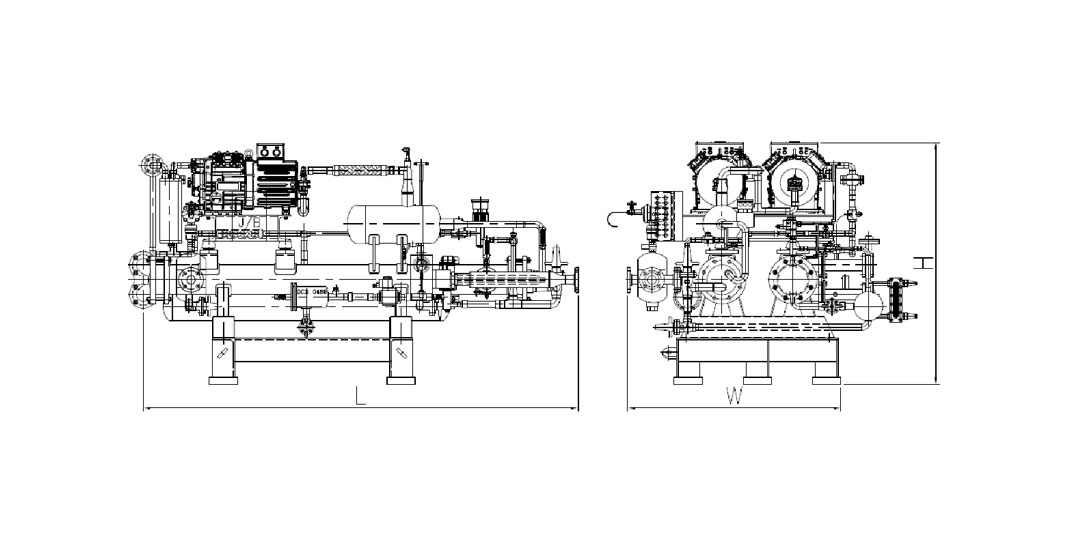

COKC 272702COOLING CAPACITY kW 50.0 100 150 220 COMPRESSOR MODEL - HGX4-465 HGX6-1240 HGX7-1860 HGX8-2470 POWER kW 17.1 47.0 53.3 91.3 REVOLUTION rpm 1,740 1,740 1,740 1,740 CONDENSER MODEL - COKC 161502 COKC 211902 COKC 271902 COKC 272702 COND.TEMP. ℃ 42.3 43.2 44.0 44.6 WATER FLOW ㎥/h 18.0 39.0 39.0 59.0 EVAPORATOR MODEL - EIKH 161950 EIKH 211944 EIKH 271926 EIKH 272738 MGO IN/OUT TEMP. ℃ 45/27 45/27 45/27 45/27 MGO FLOW ㎥/h 6.0 13.7 19.2 29.0 DIMENSION LENGTH

(mm)2,400 2,600 2,900 3,600 WIDTH

(mm)1,900 2,350 3,000 2,550 HEIGHT

(mm)1,700 1,750 1,900 1,900 PRODUCT WEIGHT(Dry) kg 1,900 2,700 2,900 3,500 - DOCUMENTS