COOLING

ROOFTOP UNIT

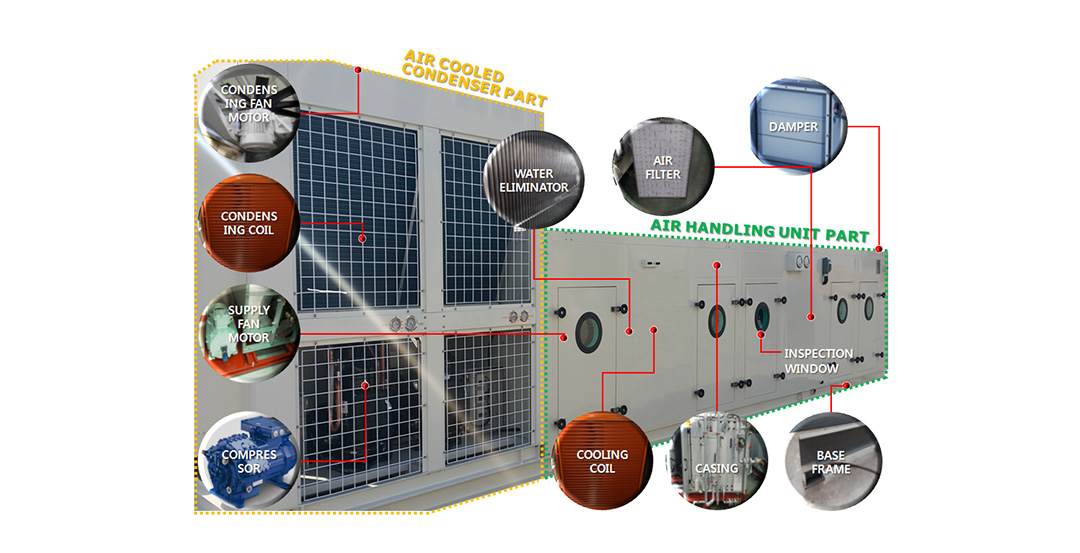

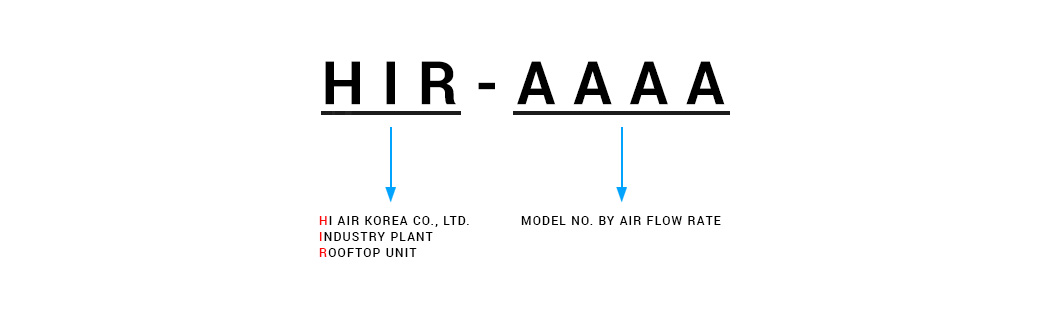

HI AIR KOREA(HAK) ROOFTOP UNIT is designed to withstand and operate optimally in some of harsh conditions in industrial plants, and it is generally installed on the rooftop. This is also called SINGLE PACKAGED AIR CONDITIONING UNIT because it is combination of AIR HANDLING UNIT and AIR COOLED CONDENSING UNIT.

HAK ROOFTOP UNIT is a cost-effective unit that can comply with stringent requirements of global standards. All of our units are designed considering optimized size, high efficiency, reliability, and maintainability.

HAK Industry plant ROOFTOP UNIT is specifically constructed to operate in various applications such as thermal power plant, refinery and petro-chemical plant, etc.

The ROOFTOP UNIT is generally required to be built using sturdy and good-valued materials so as to prolong the lifetime and be preserved. The unit has developed in close cooperation with major customers, so it can meet demanding requirements.

The Most Customizable Unit for Every Application!

-

FEATURES

CASING

AIR HANDLING UNIT Part

- 0.6~1.2 mm thick double skinned panels made of galvanized steel internal wall and external wall with epoxy

- Panels of 50 mm thickness with rock wool insulation

AIR COOLED CONDENSING UNIT Part

- Single skin steel casing with epoxy coating

BASE FRAME

- The base frame is made of carbon steel.

- Rigid in designed to support all components during shipping, lifting and operation

- Spaces between the frame are also considered for installation of drain piping

DAMPER

- Manual or motorized shut-off dampers can be provided on all AIR HANDLING UNIT inlet and outlet(Aluminum)

FILTER

- 1st stage pre filter of MERV 6(AFI 85-90 %) according to ASHRAE 52.1 or 52.2

COIL

- Coils available are for heating, cooling and condensing

- Copper tube with aluminum fins

- Cooling medium : HFC refrigerants(R-407C, R-134a), Chilled water

- Heating medium : Steam, Hot water, Electric heater

- Electric heating coils made of stainless steel elements

WATER ELIMINATOR

- Water eliminator is made of aluminum.

- 100 % efficiency at 2.54~3.51 m/s air velocity

- 55 Pa pressure drop at 2.54 m/s air velocity

- Water eliminator is recommended if face velocity is over 2.54 m/s

FAN

AIR HANDLING UNIT Part

- Centrifugal type

- Double width and Double inlet

- V-belt driven, complete with fan guard

AIR COOLED CONDENSING UNIT Part

- Direct driven axial flow type

MOTOR

- Minimum IE 2 efficiency(high efficiency)

- Cast iron casing

- IP 54/55/56/65 protection

- Power supply : 380/400/415/440/460/480Vac, 50/60Hz, 3-phase

COMPRESSOR

- Reciprocating, Scroll, Screw type

- IP 54/55/65 protection

- HFC refrigerants : R-407C, R-134a

- Available in 50/60Hz, 380/400/415/440/460/480V, 3-phase

- Power supply : 380/400/415/440/460/480Vac, 50/60Hz, 3-phase

OTHER COMPOENENTS AND ACCESSORIES

- Thermal expansion valve, Solenoid valve

- Filter drier, Accumulator, Oil separator, Receiver tank, Sight glass, Pressure gauge, others

-

OPTIONS

CASING

- Stainless steel casing(SS304 or SS316L)

- Panels of 25~40 mm thickness with rock wool insulation

FAN MOTOR & COMPRESSOR

- Spark proof fans

- Direct driven plenum fans for AIR HANDLING UNIT

- Explosion proof motors

- Explosion proof compressor

- Return fan & motor assembly

ADDITIONAL COMPONENTS

- 2nd stage medium filter of MERV 14(NBS 90-95 %) according to ASHRAE 52.1 or 52.2

- Differential pressure transmitter / switch for air filters or AIR HANDLING UNIT fans

- Windows on doors and lamps with switch for inspection and maintenance

- Humidification method : Electrode type

- Electronic expansion valve

- Additional air damper for purge operation

- Anti corrosion coating for coils(Heresite, others)

- Cooling coil : Copper tube with copper fins

- Dampers for supply, return and fresh, exhaust air connection(SS304 or SS316L)

- SS304 or SS316L Water trap

- Other refrigerants are available

RECOMMENDED ADDITIONAL UNITS

- Sand Trapping Box(STB) in case sand filtration is required

- Chemical Filter Unit(CFU) in case chemical filtration is required

-

CAPACITIES

MODEL NO. SUPPLY AIR FAN COOLING CAPACITY HEATING CAPACITY DIMENSION

(mm)㎥/min ㎥/hr Pa kcal/hr kW USRT kcal/hr kW L W H HIR-0083 83 4,950 1,800 24,000 28 8 14,000 17 6,800 1,300 1,300 HIR-0110 110 6,600 1,800 32,000 37 11 19,000 22 6,750 1,400 1,200 HIR-0165 165 9,900 1,800 47,000 55 16 28,000 33 7,000 1,700 1,300 HIR-0220 220 13,200 1,800 63,000 73 21 38,000 44 7,400 1,800 1,600 HIR-0275 275 16,500 1,800 78,000 91 26 47,000 55 7,200 1,900 1,450 HIR-0330 330 19,800 1,800 94,000 109 31 56,000 65 8,650 2,000 1,950 HIR-0385 385 23,100 1,800 110,000 127 37 66,000 76 8,650 2,150 1,850 HIR-0440 440 26,400 1,800 125,000 146 42 75,000 87 8,880 2,400 1,900 HIR-0550 550 33,000 1,800 156,000 182 52 93,000 109 9,000 2,750 1,850 HIR-0660 660 39,600 1,800 188,000 218 62 112,000 130 9,150 3,000 2,100 HIR-0770 770 46,200 1,800 219,000 254 73 131,000 152 10,600 3,150 2,350 HIR-0880 880 52,800 1,800 250,000 291 83 149,000 173 10,800 3,400 2,450 HIR-0990 990 59,400 1,800 281,000 327 93 168,000 195 11,300 3,550 1,600 HIR-1100 1,100 66,000 1,800 312,000 363 104 186,000 217 11,000 3,600 2,875 HIR-1210 1,210 72,600 1,800 344,000 400 114 205,000 238 10,850 4,000 2,800 HIR-1320 1,320 79,200 1,800 375,000 436 124 224,000 260 12,100 4,200 2,875 HIR-1430 1,430 85,800 1,800 406,000 472 135 242,000 282 11,100 4,300 2,950 HIR-1540 1,540 92,400 1,800 437,000 508 145 261,000 303 12,900 5,300 2,500 - The figures are based on below condition and can be changed as per the client's requirements.

- Outdoor conditions : 45.0 ℃ DB, 30.2 ℃ WB / Minimum -15.0 ℃

- Indoor conditions : 26.0 ℃ DB, 18.7 ℃ WB / Minimum 18.0 ℃

- The figures are based on below condition and can be changed as per the client's requirements.

-

DOCUMENTS

For more information, please contact the sales manager.

1 Technical Data of HVAC System for Industrial Buildings DOWNLOAD

1